In June, a long-standing Liberian customer contacted us again, hoping to order several lowbed semi-trailers. This customer had purchased three fuel tanker trailers and two water tankers from us the previous year, and had used them for over a year without any quality issues. This is why they sought further cooperation. Based on their needs, we recommended the 3 Axles 70 Tons Lowbed Semi-Trailer. We have exported this model extensively to the African market and have received excellent customer feedback. After we detailed the specifications, they were very satisfied. As a repeat customer, we offered them a very favorable price, which they were also very happy with. From the time the customer contacted us to the time they paid their deposit, it took less than two weeks. We will never let our customers down.

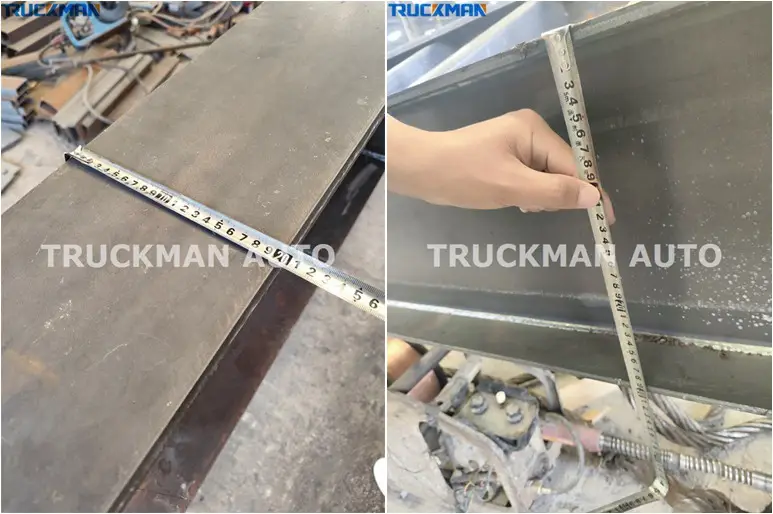

All low bed semi trailers designed by TRUCKMAN, the main beam and side beam size are higher and wider than other brand. For example, TRUCKMAN brand semi trailer’s main beam width and side beam height is 200mm and 300mm, other brand is 140mm and 220mm only. As we all know, main beam and side beam are key part of a semi trailer. This part determines trailer loading capacity and service life. Higher and wider size of main beam, loading capacity and service will be stronger and longer. Even if this way will increase our cost and down our profit, but customers use experience will be better, so we do this all time.

Except above details, we also make some others for a semi trailer. We use 900mm width mechanical ladder, wider than common use one. It means easier to load and unload the construction machinery. The widened ladder can meet the transportation needs of goods of different specifications, especially for ultra-wide or heavy equipment. The low-flat design combined with the widened ladder can disperse the load-bearing pressure and ensure the stability of the goods during transportation.

The use of waterproof cables further demonstrates TRUCKMAN’s meticulous attention to detail. Their multi-layered structure effectively blocks moisture penetration, preventing insulation degradation and short-circuit failures caused by moisture. The waterproof design prevents fire risks caused by electrical shorts and is particularly suitable for wiring harness connection points in wet areas of semi-trailers, such as the engine compartment and chassis. Semi-trailers are often subjected to high-pressure water jet cleaning and wading. Waterproof cables can withstand 0.3MPa water pressure spray and short-term immersion tests, ensuring circuit safety under extreme conditions.