As a leading trailers manufacturers, Truckman Automobile deeply understands the various challenges faced by truck operators in winter. Among them, the performance of diesel fuel in low-temperature environments is particularly critical.

In fact, diesel fuel in cold weather does not freeze into a solid like water, but undergoes a process known as “gelling.” At low temperatures, the paraffin in diesel gradually crystallizes, causing the fuel to become thick and potentially clog the fuel system.

This article will delve into the changes in diesel fuel in cold weather based on scientific principles and industry practices, and provide practical prevention strategies and solutions to help you handle winter operational challenges with ease.

Table of Contents

Understanding Diesel Fuel Behavior in Cold Weather

Diesel fuel performance in low temperatures is a focal point in the trucking industry. Compared to other fuels, diesel’s unique chemical composition makes it more prone to solidification at temperatures above the actual freezing point. This phenomenon not only affects fuel supply but may also cause broader vehicle operational disruptions.

Diesel fuel contains paraffin wax components that provide excellent lubrication and combustion efficiency under normal temperatures. However, as temperatures drop, wax molecules gradually crystallize, ultimately hindering normal fuel flow. This process involves the orderly arrangement and crystal formation of wax molecules, which is key to understanding diesel solidification mechanisms. According to relevant research, the cloud point of #2 diesel is typically in the -10°C to 0°C range, while the pour point (the temperature at which fuel completely cannot flow) may be as low as -22°C.

The following is the behavior of diesel fuel under different temperature ranges and its impact on the engine (data based on typical #2 diesel, actual values may vary slightly due to fuel batches):

- Above 0°C (32°F): Fuel flows normally and lubricates, providing optimal engine performance.

- 0°C to -10°C (32°F to 14°F): Wax crystals begin to form, cloud point appears, fuel fluidity decreases, possibly starting gelling.

- Below -10°C (14°F): Wax crystals significantly increase, reaching CFPP (cold filter plugging point), fuel flow severely restricted, engine may fail to start.

Can Diesel Freeze?

Diesel gelling is a typical reaction of fuel in low-temperature environments, but it differs from the traditional freezing concept. Generally, diesel does not “freeze” directly into a solid but affects its fluidity through a gradual solidification process.

Cloud Point: The First Stage of Diesel Solidification

The initial stage of the solidification process is the cloud point, which for untreated #2 diesel typically occurs around 32°F (0°C), when wax crystals begin to form, turning the fuel appearance cloudy and increasing flow resistance.

Cold Filter Plugging Point (CFPP)

As temperatures continue to drop, diesel reaches the cold filter plugging point (CFPP), where wax crystal sizes grow large enough to block fuel filters, interrupting fuel supply to the engine. This threshold for #2 diesel is usually a few degrees below the cloud point, potentially causing vehicle performance degradation or start failure.

Pour Point: When Diesel Truly Freezes

Finally, the fuel enters the pour point stage, becoming too thick to flow, typically occurring below -12°C for untreated fuel. Recognizing these stages helps operators develop preventive measures early to avoid sudden failures.

What Happens After Diesel Solidifies:

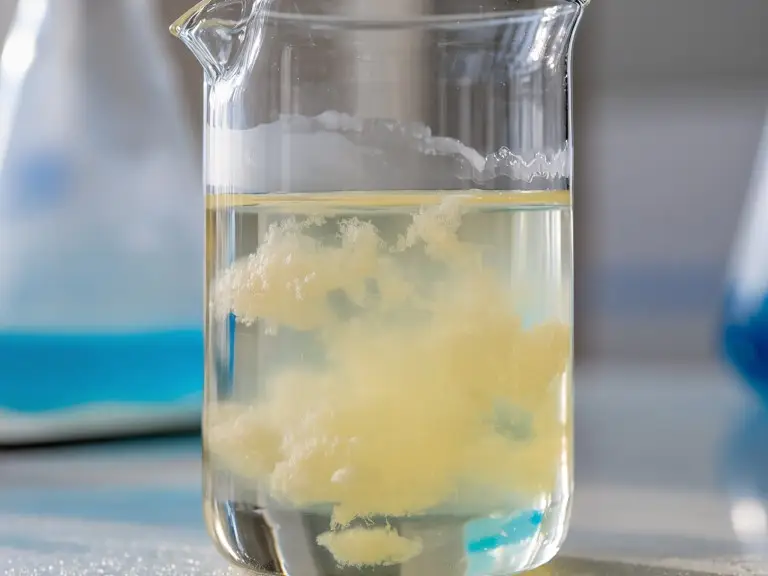

- Cloudy Appearance: The first sign of gelling is the fuel presenting a cloudy or hazy appearance, caused by wax crystals forming and separating from the solution.

- Filter Clogging: As temperatures drop further, wax crystals aggregate and solidify, forming gel that blocks fuel filters, lines, and other fuel system components.

- Vehicle Unable to Start: Fuel cannot reach the engine, leading to complete vehicle inoperability.

Common Winter Diesel Problems for Truck Operators

When winter arrives, diesel engine performance often faces severe tests. Low temperatures not only directly affect fuel but may also amplify other system issues, interrupting daily operations.

Distinguishing Between Icing and Gelling Problems

Truck operators often encounter two cold weather fuel problems: water icing and paraffin gelling. Water contamination can cause icing at higher temperatures, with symptoms including intermittent power loss and starting difficulties; in contrast, complete gelling leads to total fuel flow stoppage. Accurately distinguishing between the two is a prerequisite for selecting the correct solution.

How Cold Weather Affects Truck Performance

The impact of low temperatures extends beyond fuel, including reduced battery efficiency, increased oil viscosity, and decreased tire flexibility. Diesel vehicles are more prone to cold start obstacles compared to gasoline engines, thus requiring specialized start procedures and preventive maintenance to ensure overall performance.

Preventing Diesel Fuel Gelling in Semi-Trailers

As winter approaches, gelling risk becomes a topic that semi-trailer operators must pay attention to. Understanding its causes and implementing effective measures can significantly reduce potential losses.

How to Prevent Diesel Gelling:

- Use Anti-Gel Additives: Add diesel anti-gel agents to the fuel before temperatures drop significantly to lower the cloud point and gel point.

- Use No. 1 Diesel or Mixed Diesel: Mixing ordinary #2 diesel with #1 diesel (containing kerosene) can effectively lower the gel point. For example, a 50/50 ratio mix can lower the cloud point by more than 10°F.

- Fill Up the Tank: Keeping the tank full helps reduce condensation, thereby avoiding water accumulation and icing in the fuel system.

- Use Block Heaters: Engine block heaters can maintain fuel and engine temperature during cold nights, preventing gelling.

In addition to additives, keep the fuel tank as full as possible to minimize condensation and water accumulation risks. Choosing to park in heated areas, using engine block heaters, and prioritizing winter blended diesel can all significantly improve cold weather performance.

- Maintain a consistent fuel treatment program throughout the winter.

- Develop a comprehensive winter fuel management protocol, including regular fuel quality testing and filter replacement schedules.

What to Do When Diesel Gels

Despite preventive measures, extreme cold may still cause gelling, leading to vehicle stagnation. At this time, quick response is needed to restore normal operation.

Step-by-Step Recovery Process

The primary step is to move the vehicle to a heated environment if possible. This can effectively raise the overall temperature of the fuel system.

If unable to move, add emergency fuel additives directly to the tank to break down wax crystal structures.

After the engine starts, allow it to idle for a period to promote warm fuel circulation.

Products That Can Restore Gelled Diesel

General emergency additives can re-liquefy gelled fuel and thaw filters and lines.

It is recommended that operators carry cold weather emergency kits, including spare filters, additives, and portable heating equipment, to reduce downtime in remote areas.

Winter Diesel Management Recommendations

To effectively prevent gelling and maintain optimal engine performance, Truckman Automobile recommends a multi-layered strategy: integrating high-quality additives, appropriate fuel selection, and preventive maintenance practices.

Regularly monitor weather forecasts and proactively treat fuel before cold fronts arrive, which is key to avoiding costly downtime.

For fleet operators, establish a unified winter fuel protocol to ensure all drivers and maintenance personnel strictly adhere to it.

Additionally, investing in fuel system upgrades, such as installing fuel heaters and insulated lines, can provide long-term protection, reducing sole reliance on chemical additives.

Through these comprehensive recommendations, semi-trailer operators can maintain reliable operation under severe cold conditions while protecting equipment investments.

FAQ

What is Diesel Gelling, and How Does It Occur?

Diesel gelling refers to the process where fuel thickens into a gel-like state at low temperatures, caused by wax crystal formation, which may clog filters and interfere with engine performance.

What is the Difference Between Cloud Point and Pour Point?

The cloud point is the temperature at which wax crystals begin to form, while the pour point is the temperature at which fuel cannot flow freely.

How to Prevent Vehicle Diesel Gelling?

Use additives or anti-gel solutions, maintain a clean fuel system, and consider winterized diesel or mixing with low pour point fuel.

What is the Cold Filter Plugging Point (CFPP), and Why is It Important?

CFPP is the temperature at which fuel cannot pass through the filter, potentially leading to engine failure; it determines the lowest temperature for safe vehicle operation.

Can I Drive If Diesel Has Gelled?

It is not recommended, as it may cause severe engine damage; follow the step-by-step recovery process instead.

How to Recover from Diesel Gelling, and What Products Help?

Use fuel additives designed to break down wax crystals, added directly to the tank.

What Are the Best Practices for Managing Diesel Fuel in Winter?

Include using winterized fuel, maintaining a clean system, monitoring weather, and considering additives or anti-gel solutions to prevent gelling.